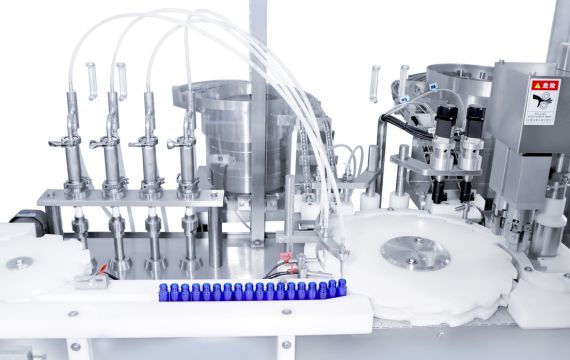

Automatic Rotary Type Monobloc Filling Machine Model: ALF3 Series

The Rotary Type Monobloc Filling Machine is specifically designed for filling inner-seal bottles and encompasses the workflow of bottle unscramble, filling, plugging, capping, and cap tightening. Given the wide variety of inner-seal bottles, this machine offers customization equipment structure to cater to the specific requirements of different customers.

- Bottle feeding adopt conveyor belt, with a turntable for ensuring stable bottle entry.

- It incorporates multiple photoelectric detection devices that detect missing bottles.

- Multiple compression of the plugs ensures a high level of sealing.

- Utilizes a constant torque capping mechanism that securely seals the caps.

- Equipped with a servo-driven constant torque and touch screen adjustment for capping torque.

- ALF3-40

- ALF3-80

|

Model |

ALF3-40 |

| Filling pump range |

3-20ml |

|

Filling nozzles |

Two heads |

| Plugging head |

One head |

|

Capping head |

One head |

| Filling speed |

30-40bpm(depend on the filling volume) |

|

Filling accuracy |

±1% |

| Supply voltage power |

380V/220V 50Hz 2.0kw |

|

Weight |

Around 880kg |

| Overall dimensions |

2200×1150×1700mm |

|

Model |

ALF3-80 |

|

Filling pump range |

3-20ml |

| Filling nozzles |

Four heads |

|

Plugging head |

Two head |

| Capping head |

Two head |

|

Filling speed |

60-80bpm(depend on the filling volume) |

| Filling accuracy |

±1% |

|

Supply voltage power |

380V/220V 50Hz 4.0kw |

| Weight |

Around 980kg |

| Overall dimensions | 2400×1300×1700mm |

Product Application

Inner plug bottles are widely used in the daily goods industry due to their numerous advantages. They provide controlled and even dispensing of liquid, excellent sealing, convenience, and environmental safety. They are commonly used for packaging products like perfumes, toners, essential oils, and antiperspirants that require repeated use.

Conveyor system

The conveyor belt for transporting bottles is adjustable based on their shape and characteristics. Such as modified by raising the side baffles and adjusting the distance between them to ensure secure and efficient transportation, regardless of the bottle’s height, width, or fragility.

Plugging system

The rotary type monobloc Filling machine is highly adaptable to the diverse range of inner plug bottles. It can handle various sizes and shapes, and our customizable robotic arm ensures perfect filling results by accommodating different plug specifications.