Automatic Bottle Washing Machine Model: ALX Series

This bottle washing machine is a fully functional cleaning machine that consists of two water and one air alternate rinsing, and can also add ultrasonic wave for rough washing if the hygiene standard is strict. It has high cleaning efficiency and low noise, and can be installed directly between the bottle unscrambler machine and liquid filling machine to realize fully automatic production.

- No damage to bottle during cleaning.

- Nozzle penetrates deep inside the bottle to ensure cleanliness.

- Suitable for glass or plastic bottle.

- Modular design, easy to replace.

- 100% pass rate for cleaning.

- ALX-60

|

Model |

ALX-60 |

| Bottle size |

20-1000ml |

|

Capacity |

40-60bpm(depend on the bottle size) |

| Water consumption |

0.6-1t/h |

|

Air consumption |

1.5m³/h,0.3-0.4kg/c㎡ |

| Supply voltage power |

380V/220V 50Hz 2.0kw |

|

Weight |

Around 400kg |

| Overall dimensions |

1460×900×1350mm |

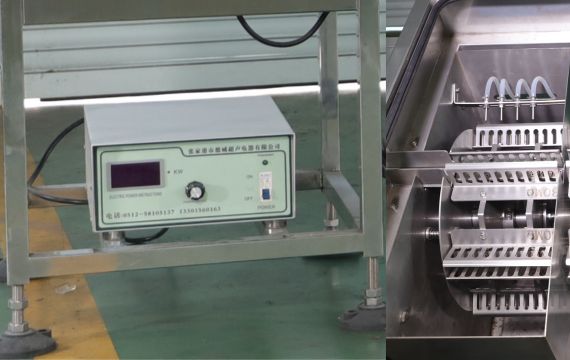

Ultrasonic cleaning system

Ultrasonic cleaning machine is one of the machines with the highest cleaning efficiency and the best effect on the market, including triple cleaning process. At first, the ultrasonic cleaner will use ultrasonic waves to simply wash the empty bottle, which is suitable for complex shape of the container.Contaminants in the dead space of the container are also decomposed and flaked off, providing greater convenience for subsequent water washing and air washing.

Modular design

Rotary bottle washer adopts mechanical template to fix bottles, each bottle has a nozzle for individual rinsing, clean thoroughly and reduce the rate of bottle loss, and reduce the amount of cleaning water. The modular design of the cleaning station eliminates the need to disassemble individual parts when the size of the empty bottles to be cleaned changes, and allows the entire module to be replaced, saving time and labor costs and improving productivity.