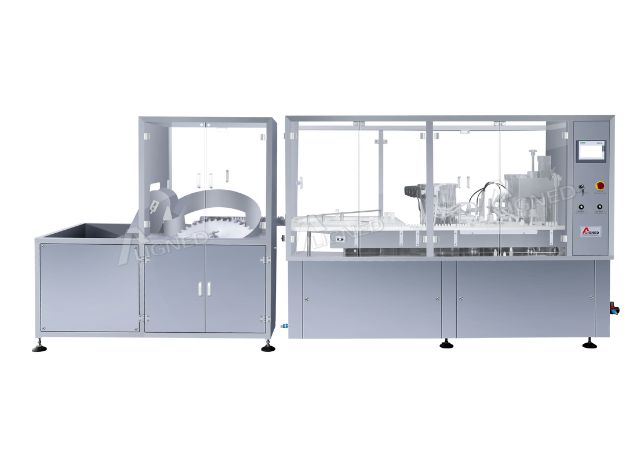

Automatic Ear Drop Filling Machine Model: ALD Series

The dropper filling machine is primarily used for filling small doses of ear drops. It is a rotary-type filling and capping machine known for its high speed and productivity, making it an ideal machine that meets GMP production standards.

- Bottle rejection design

- No bottle, no filling, one bottle one filling

- Efficient and precise filling of small doses

- High sealing accuracy to prevent leaks

- Compliance with GMP standards for pharmaceutical

- ALD-50

- ALD-100

|

Model |

ALD-50 |

| Filling pump range |

2-15ml |

|

Filling nozzles |

2heads |

| Plugging head |

one head |

|

Capping head |

one head |

| Filling speed |

40-50bpm(depend on the filling volume) |

|

Filling accuracy |

±1% |

| Supply voltage power |

380V/220V 50Hz 3.0kw |

|

Weight |

Around 1000kg |

| Overall dimensions |

2600×1150×1700mm |

|

Model |

ALD-100 |

| Filling pump range |

2-15ml |

|

Filling nozzles |

4heads |

| Plugging head |

two head |

|

Capping head |

two head |

|

Filling speed |

80-100bpm(depend on the filling volume) |

|

Filling accuracy |

±1% |

| Supply voltage power |

380V/220V 50Hz 3.0kw |

|

Weight |

Around 1000kg |

| Overall dimensions |

2600×1150×1700mm |

Product Application

To meet the demand for ear drops, our dropper filling machine is perfectly suited for filling these small doses of liquid into plastic bottles. Its high-speed operation and accurate dosing ensure efficient production and consistent quality.

With the growing awareness of pet healthcare, ear drops for pets are also becoming an important area of use. They are typically packaged in small plastic bottles, similar to eye drop bottles, to facilitate precise and controlled administration.

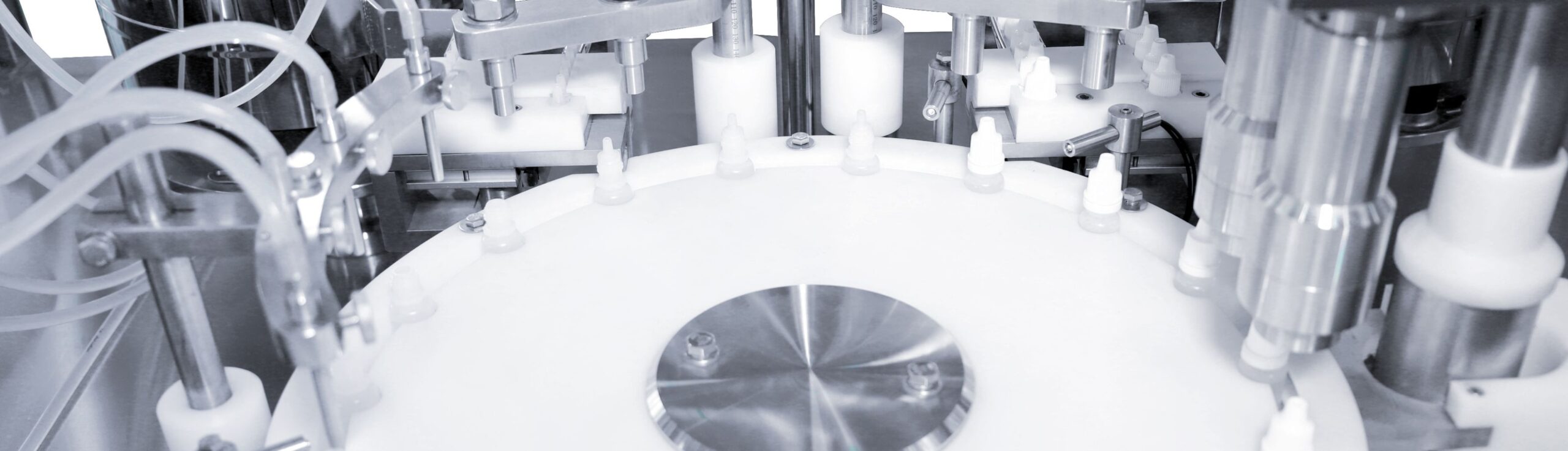

Rotary disk structure

Save valuable space in your production environment with the compact and efficient rotary disk design. Its reliable performance minimizes liquid leakage and waste, ensuring product quality and consistency.

The rotary disk automatically transfers the bottles, eliminating the need for manual intervention and reducing labor costs. Its flexibility allows it to accommodate various bottle sizes and adapt to different product requirements.

Bottle buffering area

The bottle buffering area serves as an intermediate storage zone, guaranteeing uninterrupted filling. Even during machine operation, operators can replenish empty bottles promptly, ensuring continuous production and boosting efficiency,whether it’s a high-speed or low-speed filling machine. With bottle rejection design.