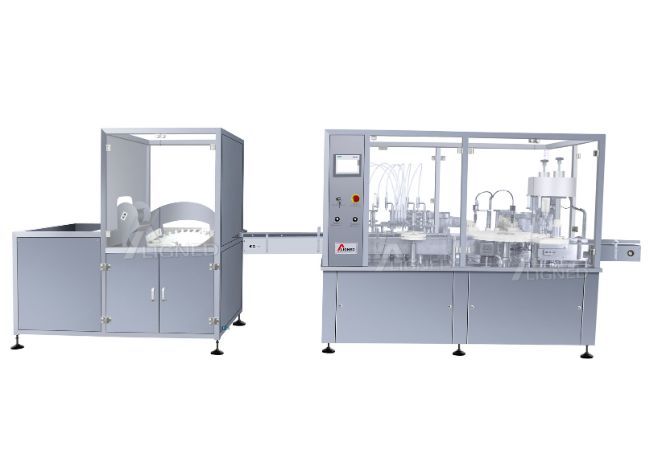

Model ALFC18/12 Automatic Filling Machine

Automatic Liquid filling and capping machine can realize the filling of light liquid products for plastic bottles and glass bottles.

-Liquid buffer tank 50L with auto liquid feed valve and Liquid pipe dispenser.

-SS316L Piston Pump with check valve application prevent leakage from nozzle.

-Index wheel adopt Nylon material, it’s changeable to fit to different bottle diameter without tool.

-Cap unscrambler with vibrator, it’s adjustable height to suit to different bottle height.

-PLC controller Auto stop machine when index wheel overload/block, No bottle no filling.

What is liquid filling machine

Liquid filling machines help producers to fill liquid products more efficiently, accurately, economically and hygienically. These machines operate on various principles, including volumetric, gravity, and net weight.

Liquid filling machines are widely used in a variety of industries, including food, daily necessities, pharmaceutical and chemical industries. These machines are used to fill a range of products, including Syrup, oil, oral liquid and nasal spray.

Automatic Filling and Capping monobloc is customized for bottle liquid filling and plastic screw cap capping (alternative alu cap), it’s suitable for low output.

The machine able to be used for filling glass or plastic bottles with light liquids, it is simple in function but has great flexibility.

The machine described combines innovative features to enhance efficiency and productivity in the bottling process.

The machine offers efficient and reliable filling, plug insertion and capping for inner plug bottles, providing excellent sealing performance, operational safety, and precise functionality.

The machine is specially designed for spray bottle filling, which solves the difficulties of adding spray nozzles, can be applied to perfume spray, nasal spray, etc.

This machine can realize film forming, filling and sealing, and is suitable for the preservation and use of materials such as medicine, dairy products and health care products in unit dose.

Machine By Application

The machines apply to all kinds of produces, according to the produces choose the right machine.

Machine By Different Pump

Eyedrop fiiling machine

Eye Drops Filling Machine is equipped with a state-of-the-art sterile system, ensuring the highest level of sterility in the production process. The machine incorporates a laminar flow hood, self-purification zone, and sterile glove isolation to maintain a controlled and sterile environment. These features eliminate the risk of contamination and guarantee the integrity of the eye drops.

Ear/Nose drop fiiling machine

The dropper filling machine is primarily used for filling small doses of nasal or ear drops. It is a rotary-type filling and capping machine known for its high speed and productivity, making it an ideal machine that meets GMP production standards.

Automatic Cartoning Machine

The Model DXH-220 automatic cartoning machine is high output design, max capacity around 200boxes/min, the leaflet fold range 1-4 fold

The Model DXH-130 automatic cartoning machine suitable for packing all kinds of bottle into the box, the max capacity around 100boxes/min, but it depend on the bottle and box size

That Customer Trust Aligned

The Ukrainian customers personally came to Aligned ‘s factory for ALF3 filling machine acceptance. We showed the customer the machine made in strict accordance with the contract requirements and FAT report, conducted a rigorous quality inspection of the machine together, and provided detailed training. Finally, we received satisfactory feedback from the customer.

The Algerian customers, who has cooperation experience with Aligned, came to our company personally and shared the experience of usage. We sincerely listened to the their ideas and optimized the machine, then the customers ordered the ALF filling line again.

We visited customers in Bangladesh to understand their use of the ALFC filling machine. They are very satisfied with our considerate after-sales service, and we got the most accurate information from this communication for the innovation and optimization of the machine.

Exhibition

- 2023

- History

Details

Related Machine

Why Choose Us?

Aligned machinery is professional pharmaceutical equipment manufacturing and supplying company provides a comprehensive range of services that are designed to meet the unique needs and requirements of our clients. We offer a one-stop procurement solution that simplifies the supply chain process, customized solutions to meet specific needs, and comprehensive equipment training to ensure efficient and effective equipment operation. Our experience in overseas commissioning and commitment to quality make us the preferred choice for companies in the pharmaceutical industry.

Yes, we offer commissioning services for liquid filling machines internationally. Our experienced technicians are available to travel to your site to ensure that your machine is installed and running correctly.

We have been in the business of liquid filling machine production since the beginning of our company, and have 20 years of experience in R&D and production so far. We can provide strong technical support to our customers

Yes, our team of experts can provide customized solutions for your liquid filling needs. We work closely with our clients to understand their specific requirements and design machines that meet those needs.

We offer a range of liquid filling machines, including piston fillers, gravity fillers, and net weigh fillers. We also offer a variety of accessories and add-ons to customize your machine for your specific application.

We offer ongoing technical support and assistance for all of our liquid filling machines. Our team of experts is available by phone, email, or on-site to help troubleshoot any issues that may arise and to provide ongoing maintenance and support.