Auto Plastic Ampoule Filling And Sealing Machine Model: DGS Series

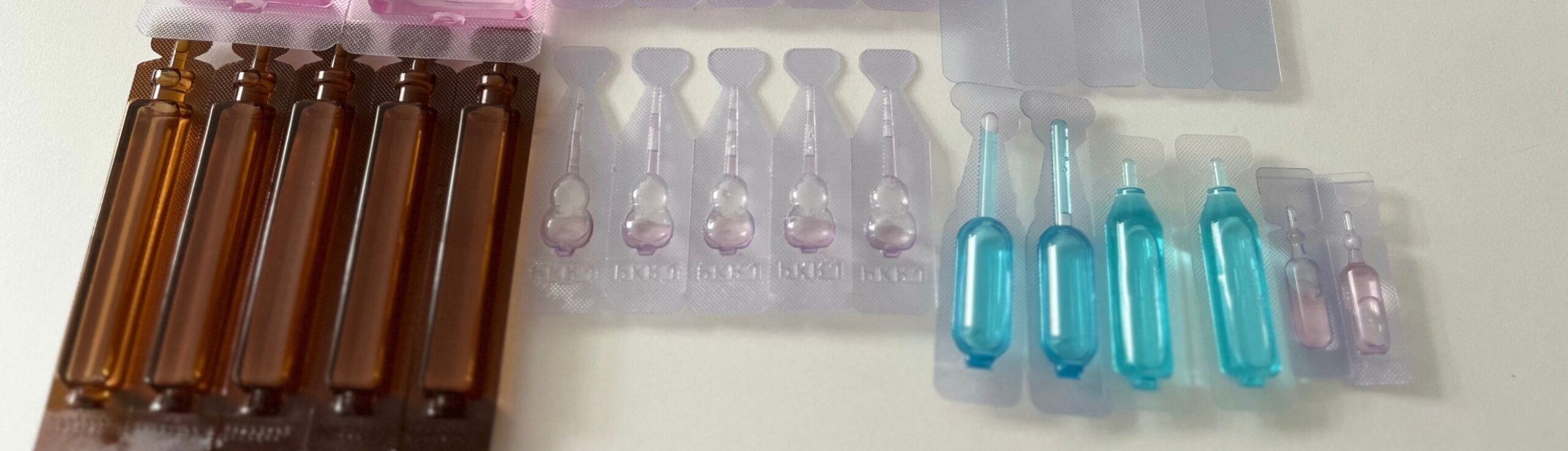

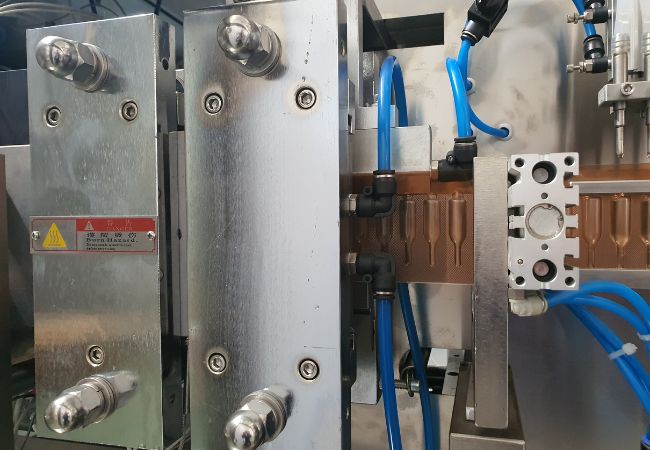

The plastic oral liquid filling machine consists of several stations: film forming, filling, sealing, and cutting station. It is suitable for the unit dose of medicine, drinks, dairy products, health products, food, cosmetics, perfume, agricultural medicine, fruit purees, etc

- Servo motors control traction,

- It can design all kind of shape ampoule

- Efficient and precise filling of small doses

- High sealing accuracy to prevent leaks

- Ampoule can option single or multiple units discharge

- DGS-240

- DGS-118

| Model |

DGS-240 |

| Max Forming Depth |

12mm |

|

Cutting Frequency |

0-25 times/min (according to your products) |

|

Packing material |

PVC/PE PET/PE |

| Filling range |

1-100ml |

|

Supply voltage power |

380V/50Hz 7KW |

|

Model |

DGS-118 |

|

Max forming depth |

16mm |

| Cutting frequency |

0-25 times/min (according to your products) |

|

Packing material |

PET/PE, PVC/PE |

| Filling volume |

1-50ml |

|

Supply voltage power |

380v/50Hz 7kw |

Product Application

The plastic oral liquid filling machine is suitable for unit dose packaging of various products, including medicines, beverages, dairy products, health supplements, food items, cosmetics, perfumes, agricultural chemicals, fruit purees, and more. This form of single-use packaging provides great convenience for use in any setting.

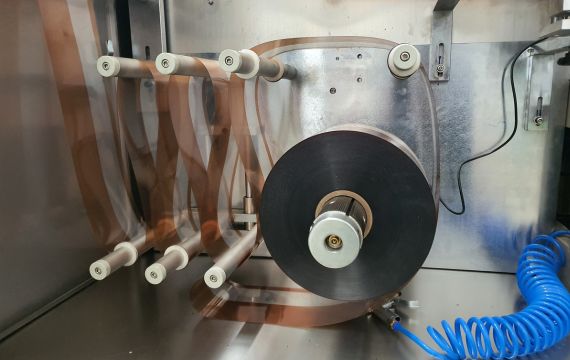

Film station

The film forming station adopt a roll of film is utilized to create stand-up ampoules helps broaden the range of products.The stand-up ampoules can be utilized for various applications, such as packaging liquid medicines, beverages, sauces, condiments, cosmetics, personal care products, and more. The upright design of the ampoules provides better visibility, easier storage, and enhanced user experience.