Automatic Liquid Filling Machine Model: ALF Series

Oral liquid filling machine is the ideal machine to achieve high precision filling of light liquids, is capable of filling a large span from 10ml to 1000ml, and maintains high precision and speed. It can adapt to the strict requirements of liquid filling in the ever-changing market and is a necessary filling machine for the production line of bottled liquids such as oral liquid and syrup.

- Liquid level following device, prevents foaming.

- Touch screen to adjust the filling volume

- Fits a wide range of bottle sizes and shapes

- Equipped with liquid buffer tank

- Stable filling head lifting mechanism

- AFL-4

- ALF-8

- ALF-12

|

Model |

ALF-4 |

|

Filling pump range |

10-60ml, 30-125ml, 50-250ml, 200-500ml, 500-1000ml |

|

Filing nozzles |

4 heads |

| Filling speed |

40-60bpm |

|

Filling accuracy |

±1% |

|

Supply Voltage |

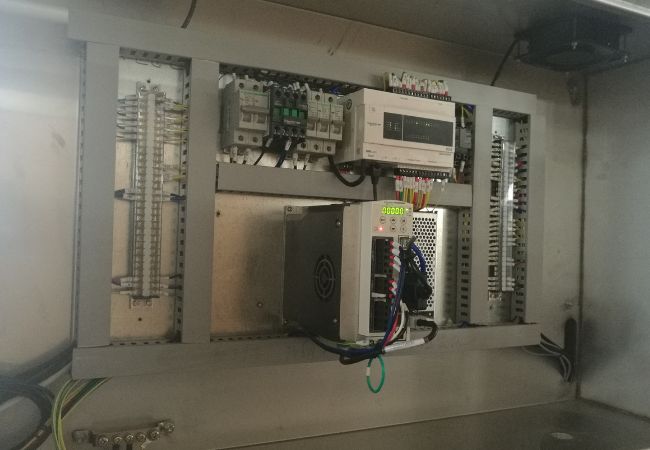

380V/220V 50Hz 0.75kw |

| Overall dimensions |

1300×1000×1800 |

| Weight |

500kgs |

|

Model |

ALF-8 |

|

Filling pump range |

10-60ml, 30-125ml, 50-250ml, 200-500ml, 500-1000ml |

|

Filing nozzles |

8 heads |

| Filling speed |

60-80bpm |

|

Filling accuracy |

±1% |

|

Supply Voltage |

380V/220V 50Hz 0.75kw |

| Overall dimensions |

1600×1000×1800 |

| Weight |

800kgs |

|

Model |

ALF-12 |

|

Filling pump range |

10-60ml, 30-125ml, 50-250ml, 200-500ml, 500-1000ml |

|

Filing nozzles |

12 heads |

| Filling speed |

70-100bpm |

|

Filling accuracy |

±1% |

|

Supply Voltage |

380V/220V 50Hz 0.75kw |

| Overall dimensions |

1900×1000×1800 |

| Weight |

1000kgs |

Product Application

The oral liquid filling machine is the best choice for filling various sizes of bottles of medication. It can be filled quickly and precisely to meet the manufacturer’s requirements for large output. Due to the natural advantages of single-sealed, easy-to-take, friendly to people with swallowing difficulties, and irreplaceable in Chinese medicine preparation, oral liquids will continue to occupy a huge share of the pharmaceutical market and are the main choice for consumers and pharmaceutical companies.

Filling station

The filling head is an important working unit in the liquid filling machine. Its lifting system is controlled by cams for smoother operation without tilting and shaking, which is a great guarantee for the stability of the filling process. Secondly, the filling process adopts liquid level following method to avoid foaming and liquid splashing. In addition, the filling head has a suction back device to prevent dripping, which helps to ensure the accuracy of filling and avoid contamination of bottles or conveyor belts.