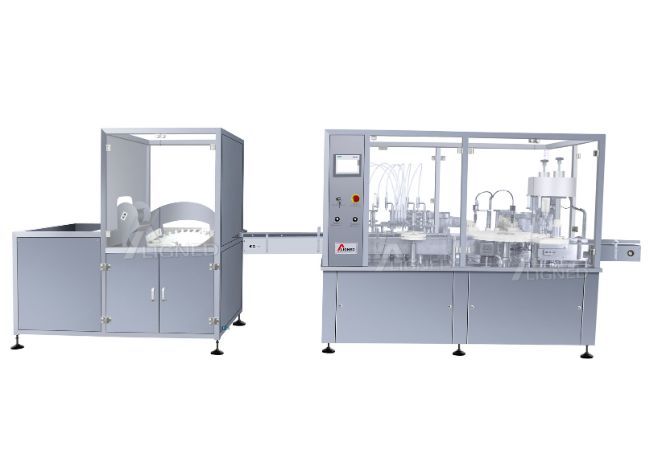

Auto Liquid Spray Filling Machine Model: ALP Series

Spray bottle filling machine not only enables precise filling of bottles of many different sizes and shapes, but its greatest advantage is that it can be used for nozzles of various shapes, thus adapting to the ever-changing pharmaceutical market demand. As a fully automatic filling system, it offers convincing performance in terms of filling accuracy and speed.

- Precise capping.

- Bottle counter records number of finished bottles.

- Multiple inspection and shutdown protection devices.

- Multiple bottle index devices.

- Compliance with GMP standards for pharmaceutical.

- ALP-40

- ALP-80

|

Model |

ALP-40 |

|

Filling pump range |

10-100ml |

| Filling nozzles |

4 heads |

|

Spraying head |

single head |

|

Capping head |

single head |

| Filling speed |

30-40bpm(depend on the filling volume) |

|

Filling accuracy |

±1% |

| Supply voltage power |

380V/220V 50Hz 3.0kw |

|

Weight |

Around 800kg |

| Overall dimensions |

2400×1350×1700mm |

|

Model |

ALP-80 |

| Filling pump range |

10-100ml |

|

Filling nozzles |

8heads |

| Spraying head |

two head |

|

Capping head |

two head |

| Filling speed |

60-80bpm(depend on the filling volume) |

|

Filling accuracy |

±1% |

| Supply voltage power |

380V/220V 50Hz 3.0kw |

|

Weight |

Around 980kg |

| Overall dimensions |

3200×1450×1750mm |

Product Application

Automatic spray filling machines can adapt to bottles of different shapes such as round, oval, and bottles of different materials such as glass and plastic. Widely used in nasal sprays, disinfectants, detergents, cosmetics, perfumes and other products.

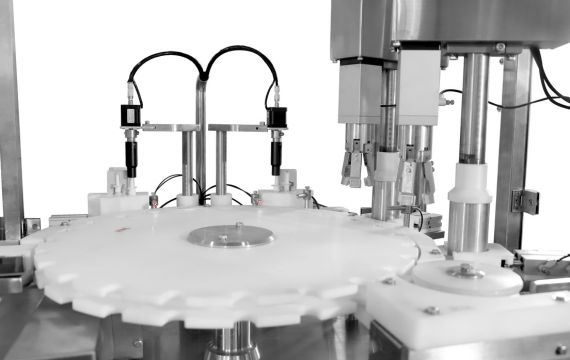

Three-jaw capping structure

Spray filling machine adopts a three-jaw capping head, which is capable of capping bottles of any shape and material, and is more suitable for caps of irregular shapes such as spray bottles. Its convenience is also reflected in the fact that the capping head does not need to be replaced when the cap is changed, and only the distance between the jaws needs to be adjusted, making the production line more compatible and a cost-effective choice.

Monobloc structure

The machine has multiple shutdown alarm devices, when the empty bottle reserve is insufficient, the filling mouth is misaligned, or the liquid in the buffer tank is less than the standard line, the machine will stop filling and alarm in time, which effectively guarantees the finished product rate. The problems with the machine will also be displayed on the touch screen, which is easy for us to adjust at any time.