Auto Liquid Filling and Stoppering Machine Model: ALS Series

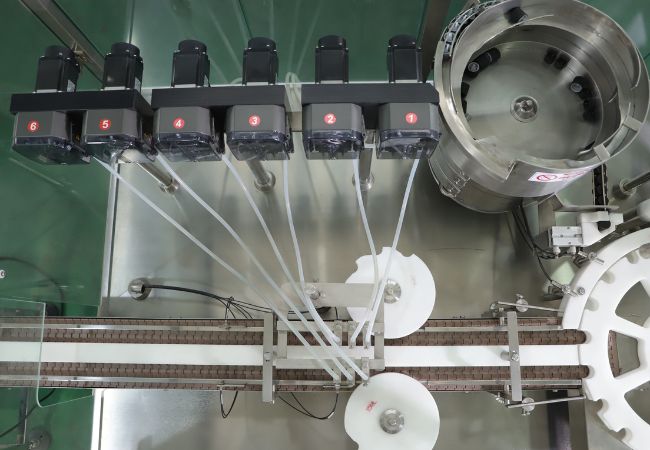

The automatic liquid filling and stoppering machine described combines innovative features to enhance efficiency and productivity in the bottling process. It is designed specifically for cap and seal integrated bottles, offering strong sealing capabilities and reducing production errors. The machine incorporates precise mechanical arms for stable gripping and secure placement of caps. Its mechanical components are wear-resistant and durable, ensuring longevity and reliability. Additionally, the machine allows for individual adjustment of filling quantities for each pump, providing versatility in production.

- Reduced production errors

- Precise control over the filling process

- Accommodate various types of filling pumps

- Precise mechanical arms and fiber optic control

- Compliance with GMP standards for pharmaceutical

- ALS-40/2

- ALS-40/4

- ALS-80/4

- ALS-80/6

- ALS-80/8

|

Model |

ALS-40/2 |

|

Filling pump range |

10-100ml |

| Filling nozzles |

Two heads |

|

Plugging head |

One head |

| Capping head |

One head |

| Filling speed |

30-40bpm(depend on the filling volume) |

|

Filling accuracy |

±1% |

| Supply voltage power |

380V/220V 50Hz 3.0kw |

| Weight |

Around 850kg |

| Overall dimensions | 2400×1150×1700mm |

|

Model |

ALS-40/4 |

|

Filling pump range |

10-100ml |

| Filling nozzles |

Four heads |

|

Plugging head |

One head |

| Capping head |

One head |

|

Filling speed |

40-50bpm(depend on the filling volume) |

| Filling accuracy |

±1% |

|

Supply voltage power |

380V/220V 50Hz 3.0kw |

| Weight |

Around 850kg |

| Overall dimensions | 2400×1150×1700mm |

|

Model |

ALS-80/4 |

|

Filling pump range |

10-100ml |

| Filling nozzles |

Four heads |

|

Plugging head |

Two head |

|

Capping head |

Two head |

| Filling speed |

60-70bpm(depend on the filling volume) |

|

Filling accuracy |

±1% |

| Supply voltage power |

380V/220V 50Hz 4.0kw |

|

Weight |

Around 850kg |

| Overall dimensions |

3200×1300×1700mm |

|

Model |

ALS-80/6 |

| Filling pump range |

10-100ml |

|

Filling nozzles |

Six heads |

| Plugging head |

Two head |

|

Capping head |

Two head |

| Filling speed |

70-80bpm(depend on the filling volume) |

|

Filling accuracy |

±1% |

| Supply voltage power |

380V/220V 50Hz 4.0kw |

|

Weight |

Around 850kg |

| Overall dimensions |

3200×1300×1700mm |

|

Model |

ALS-80/8 |

| Filling pump range |

10-100ml |

|

Filling nozzles |

Eight heads |

| Plugging head |

Two head |

|

Capping head |

Two head |

| Filling speed |

70-90bpm(depend on the filling volume) |

|

Filling accuracy |

±1% |

| Supply voltage power |

380V/220V 50Hz 4.0kw |

|

Weight |

Around 850kg |

| Overall dimensions |

3200×1300×1700mm |

Dual Robotic Arms

By incorporating dual robotic arms and connecting them to multiple capping machines, the machine can achieve higher efficiency and productivity. The robotic arms can work simultaneously, allowing for the handling and capping of multiple bottles in parallel. This reduces the time required for the capping process and increases the throughput of the machine.

Dual Conveyor Belts

The dual parallel conveyor belts significantly enhance the machine’s productivity by enabling the processing of a higher number of bottles concurrently. This reduces the time required for each filling and capping cycle, effectively increasing the overall production speed of the machine. With two bottles being fed into the turntable simultaneously, it ensures a continuous and efficient operation as the two capping machines or robotic arms can work in tandem to cap the bottles.