Aligned Mission

Do the right things,

To help customers optimize the production standard with one stop solution.

To help personnel realize both happiness of substance and spirit.

To help China’s science and technology go towards the world, contributing to human health and sustainable development.

Aligned Service

No matter where in the world the customer is located, our professional technical team will come to the customer’s factory to assist in the installation and commissioning of the equipment to ensure its smooth production.

If customers have any questions after purchasing the machine, they can contact us by phone, email and website backstage, etc. Professional staffs are available online to provide timely answers for customers.

Our professional technical team will help customers to complete the project engineering construction, solve all problems including production site, machine and personnel, and help customers to obtain production certification.

Customers can present their needs with confidence because our team has strong R&D capabilities and can develop new technologies and open up new markets. More than 40 patent certificates verified our strength.

Main Machines

This syrup filling machine can be used for filling syrup or liquid in the range of 10-1000ml, and is suitable for various bottle materials. Compared with similar machines, it has outstanding advantages in filling syrup and other liquids with certain viscosity, and the accuracy and speed can be strongly guaranteed.

The high speed spray bottle filling machine with powerful compatibility is capable of gripping and mounting a wide variety of spray heads of different shapes with precision. The machine can achieve a stable high output of 80 bpm, thus meeting the different needs of customers.

This machine is an indispensable machine in liquid filling production line, which can achieve high speed filling of cylindrical bottles of liquid. The machine consists of a conveyor belt, servo motor controlled piston pump, filling nozzle, liquid buffer tank and turntable, which can adapt to a wide range of filling needs.

The eye drops filling machine is specially designed to meet the high standards of consumers and the market for eye drops. It integrates filling, corking and capping with high efficiency laminar flow hood to achieve clean class A, which can guarantee the maximum product compliance with hygiene standard requirements.

The ear drop filling machine is an ideal machine that achieves a balance of productivity and accuracy. It uses peristaltic pumps for filling and mechanical arms for grabbing and transporting the stopper or cap. Operators can control the filling volume through PLC screen, which is easy to adjust and can be learned with only simple training.

Plastic ampoule filling and sealing machine is a machine with mature technology and strong productivity support. It adopts high-precision peristaltic pump, and the filling capacity of single bottle can reach 95%. There are two sets of systems to control the whole machine operation and filling station respectively, bringing the maximum production efficiency.

Aligned Case

- Tanzania

- Algeria

- Spain

- India

- Tureky

Tanzania

From 2018 to 2023, Aligned helped Tanzanian pharmaceutical companies build their own solid production lines, liquid production lines and independent laboratories from scratch. Facing serious traffic control issues during the epidemic, three trips were made to Tanzania for machine installation, commissioning and customer training.

Algeria

Based on the trust and brand recognition of Aligned, the pharmaceutical company in Algeria gave us the project of establishing a factory branch. We built a clean room, installed water system and delivered a lot of equipment to the customer in batches. The engineering team went to Algeria several times for the installation and maintenance of the project, and now it has become a model project for Aligned in Algeria.

Spain

Due to the great success of two projects in Algeria, our partner has full trust and recognition on our service quality and introduced us to the pharmaceutical company in Spain. After the site visit to aligned, the Spain client got a better understanding of our strength and cooperated with us to build solid formulation line, liquid filling line and water treatment system.

India

To meet the client’s needs, our technical team was dispatched to the client’s company in India to conduct an investigation and gain a deep understanding of their requirements. Through close collaboration with the client, we successfully provided a range of innovative solutions, which improved their production efficiency and product quality.

In this project, we not only provided customized solutions but also offered comprehensive services, including equipment installation, debugging, and training. We always prioritize our clients and strive to deliver the best services and support.

Tureky

At the end of 2015, Aligned was approved by the customers to contract the entire project for the construction of its branch company. In mid-2016, the order was confirmed and delivered, the engineering team went to the site to complete the commissioning and installation of the air condition system and machines, and the manager personally went to the site to supervise the work and assigned technical engineers to provide after-sales service for up to 6 months, showing the high importance Aligned attaches to the customer and the project. The project is progressing well and has become our demonstration project in Turkey.

Application Area

Get an Instant Quote

-

One Stop Solution Provider, For 500+ End users.

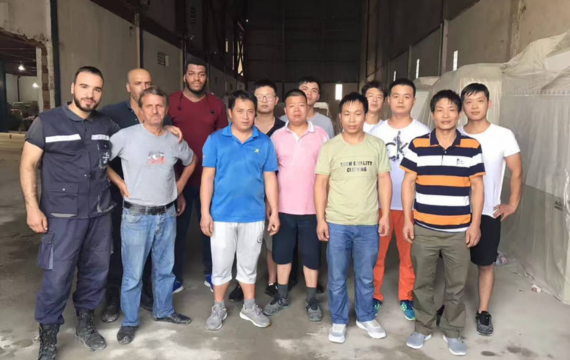

Aligned Team

Aligned Team